In the modern textile industry, highly breathable fabrics have become an important product. They not only meet the needs of customers in terms of functionality, but also lead the trend in terms of fashion. So, how to effectively create this special fabric? We start from every aspect of production and analyze it from a comprehensive perspective.

The production of highly breathable fabrics first requires the selection of suitable raw materials. Typically, synthetic fibers such as polyester and nylon are widely used due to their excellent breathability and durability. At the same time, natural fibers such as cotton and linen can also be processed through specific processes to achieve better breathability.

Next, in the weaving process, by adjusting the weaving method and density of the yarn, the breathability of the fabric can be significantly improved. For example, special mesh weaving or warp knitting technology is used to give the fabric a certain pore structure to promote air circulation.

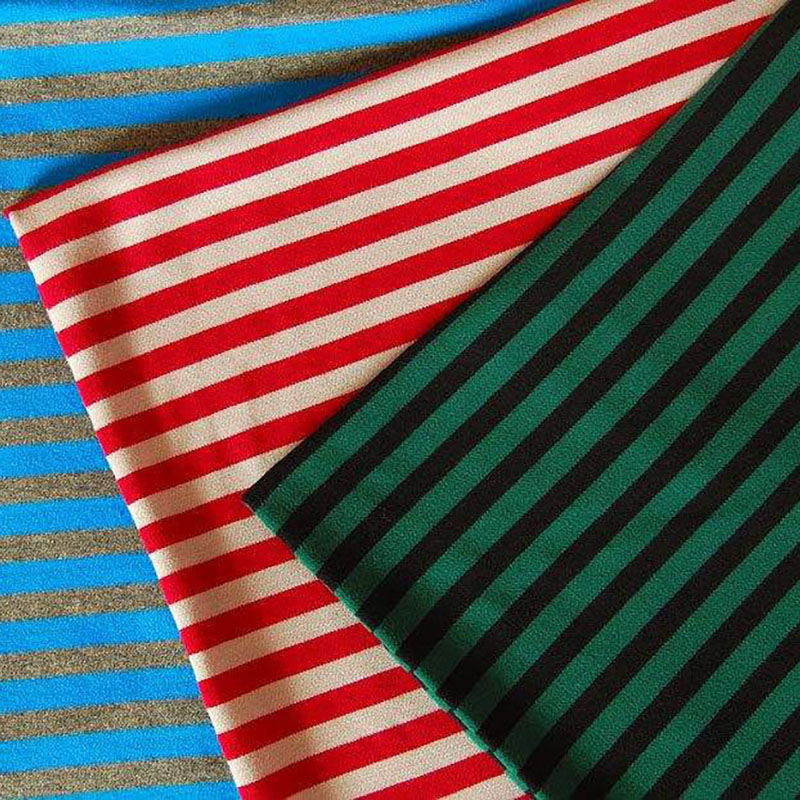

After weaving is completed, the fabric usually needs to undergo a series of post-processing to enhance its functionality. Through coating, dyeing and finishing processes, the breathability and other properties of the fabric can be further improved. In addition, antibacterial and anti-fouling treatments also help improve consumers’ experience.

Finally, strict quality testing is conducted to ensure that the highly breathable fabrics produced meet relevant standards. This technology has been widely used in sportswear, outdoor equipment and technical textiles. With the continuous advancement of technology, highly breathable fabrics in the future will be more diversified and personalized.

By conducting in-depth analysis of the production process of highly breathable fabrics and understanding their technical processes and application fields, we can not only master new textile technologies, but also lay a solid foundation for improving product competitiveness.